Garri processing technology in Nigeria

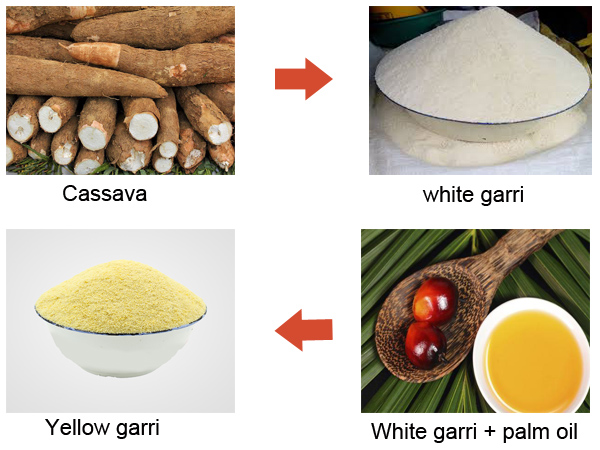

It is estimated that 70% of cassava is produced into garri in Nigeria, therefore garri processing in Nigeria is very common. In Nigeria, garri includes white garri, yellow garri and liebu garri. White garri is most common garri in Nigeria which is produced by cleaning, washing, peeling, grinding, fermentation, dehydrating and frying. Yellow garri is processed like white garri, but it need to add palm oil to get yellow color, which is commonly found in South-South and South-East area in Nigeria. And Ijebu garri has a sharp taste and is liked by people from Western area in Nigeria, it ferments for 7 days and do not add palm oil. This article mainly introduce the white garri processing in Nigeria.

White garri & yellow garri

White garri & yellow garri

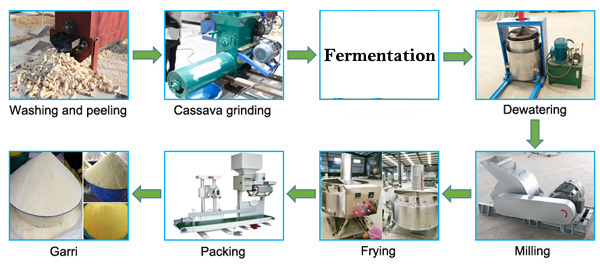

Here are the detail analysis of garri processing in Nigeria:

Nigeria's industrialization is not high, and at present garri processing in Nigeria is mainly small scale family-style workshops, where the cassava are washed, grinded, fermentated,dehydrated and fried to garri. Modern automatic garri processing in Nigeria uses automated continuous equipment to complete the entire garri production process. The main equipment used includes dry sieve, paddle washing machine, cassava peeling machine, grinding machine, hydraulic press, garri fryer, garri packaging machine, etc.

Garri processing

Garri processing

1) Washing stage: Manual small-scale garri processing in Nigeria mainly relies on manpower washing, which not only wastes manpower and time, but is high water consumption. The mechanized production is equipped with a dry sieve and a paddle washing machine for washing step. The dry sieve removes large particles like stones, weeds and sand first, and the washing machine further wash away the sediment, dust and other impurities attached to the cassava skin. Equipment processing has the characteristic of thorough cleaning, large handling capacity, high efficiency and energy saving.

Cassava washing machine

Cassava washing machine

2) Grinding stage: Generally, mechanical equipment grinding is required for garri processing in Nigeria. However, the grinding efficiency of different equipment is different, the higher the grinding efficiency of the equipment, the more thoroughly the cassava is broken, and the garri yield is higher. Customers can choose the right equipment to increase garri production and economic benefit according to their own budget and requirements.

Cassava grater

3) Dehydration stage: Traditional garri garri processing in Nigeria requires fermentation grated cassava for 1-2 days and then dehydrate it. The modern automatic garri production line does not require fermentation to directly dewater garri, which greatly improving production efficiency. Small-scale garri dehydration uses a hydraulic press, which is easy to operate and cover small footprint. For large-scale garri dehydrating, plate frame filter press can be used, which has good dehydration effect, large processing capacity and high degree of automation. In the dehydration stage, the water in the cassava pulp is mainly discharged by physical pressure, which is convenient for the next step of frying.

Garri dewatering machine

Garri dewatering machine

4) Fry stage: Traditional garri frying is done by homemade garri fryer. Unlike traditional garri processing in Nigeria, the modern garri processing plant uses stainless steel garri frying machine, which not only effectively avoids garri pollution, but also automatically controls the temperature and avoids sticking.

Garri is one of the favorite staple foods for Nigerians. Nigerians consume an average of 7.7 million metric tons of garri per year, but the actual demand for garri is 12 million metric tons. This requires Nigerian to improve the efficiency of garri processing in Nigeria to meet domestic demand. The modern garri processing plant is the key to improving the efficiency of garri production, as it will reduce the waste of traditional garri production and increase the profit of the garri processing in Nigeria. Therefore it is necessary to adopts modern garri processing machine to processing garri. Doing Company is a professional manufacturer of cassava deep processing equipment. We can customized garri processing equipment for customers according to requirements and budget. If you want to engage in garri processing business, welcome to leave us a message.

PREV:Production technology of potato in Pakistan

NEXT:Why do Africans choose to buy cassava peeling machine in China ?

Leave a message about Garri processing technology in Nigeria

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I Just learning

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others